Carbon Footprint of One Parking Space

*This research is the prerequisite of an urban design project. For the design project, please see here:

SHAPING URBANSCAPE BY ZONING CODE: AN URBAN METABOLISM PERSPECTIVE

Propose for a New Parking Paradigm for Dallas

Introduction

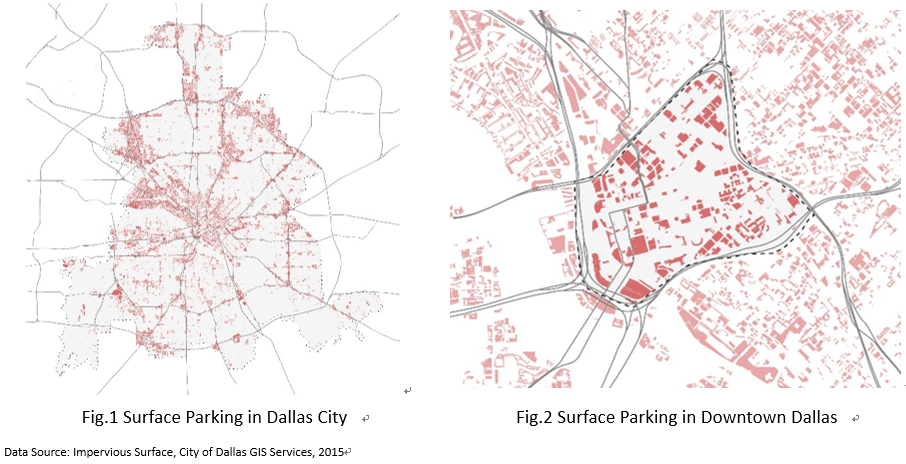

In some of the cities in United States, the footprint of parking lots has occupied more than 1/3 of the land area (Ben-Joseph 2015), which makes it the most outstanding landscape of the built environment. It represents the increasing car ownership since 1910s and the American lifestyle. In the case of Dallas, Texas, surface parking footage is 781.8 million square feet, which occupied 8% of the surface and provided about 2.4 million parking spaces, while the population is 1.3 million. As for downtown, the percentage goes up to 18.4% and provided about 26.8 thousand parking spaces.

The emission and oil consumption are two parts of the environment impact of automobile, however another aspect has often been ignored and overlooked, that large portion of the time cars are immobile, namely, they are occupying a parking space. And the parking space is paved, using asphalt or concrete, by roller and paver. From this perspective, the demand for parking makes that a hybrid car has the same environmental impact as a high-emission muscle car.

The result of huge amount of parking, especially in urban areas, is in accordance with city planning zoning ordinance that require a minimum number of parking spaces. And because building a parking space requires the material and machine to operate during the construction, it has a relatively fixed carbon emission factor. Consequently, the minimum parking requirement becomes an institutional carbon generator. This research tries to calculate what is the carbon footprint of building one parking space, in the case of downtown Dallas, and based on the result, to propose a new land-use paradigm to reduce the carbon emission.

Method

This research uses the Life Cycle Assessment (LCA). It takes into account the product’s full life cycle: from the resource extraction of raw material, production, use and recycling to the disposal of the remaining waste. The LCA consists of four phases: Goal and Scope definition, Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA), and Interpretation (European Commission and Joint Research Centre 2010). It helps to understand and quantify the magnitude and significance of the potential environmental impacts, in this case carbon emission and resource consumption, associated with parking asphalt pavement throughout its entire life cycle.

After understanding and quantifying the impacts, this research proposes a new land-use paradigm to reduce the carbon emission. Besides carbon emission, asphalt pavement has other environmental impact such as micro-climate, heat island effect, and surface runoff. However, this research focuses mainly on the carbon emission part.

Life Cycle Inventory

Before the construction, engineer will firstly calculate the appropriate thickness of the pavement structure. Most of the pavements are characterized as a layered system that consist of different materials and each layer contributes to the overall strength and function of the structure. Most of the parking lots are built on a foundation of a fine graded soil to provide a platform to work on. This paper exclusively examines the surface parking lot for passenger cars, which is classified as light-duty traffic and would contain the least overall thickness.

Once the subgrade has been properly prepared, most pavement designs will require an aggregate layer be placed over the existing site soils, which provides some load-carrying structure and improves the working platform for the construction equipment necessary to place asphalt paving materials. Following the placement and compaction of the soil and aggregate layers, two or more layers of asphalt pavement are added to complete the pavement structure. The most common approach is to place one or more base asphalt base course layers over the aggregate layer, which are characterized by larger aggregates and thicker layers. Finally, a surface mixture as the final riding course. The mix design used here is provided by Interactive Pavement Design Guide of Plantmix Asphalt.

Life Cycle Impact Assessment

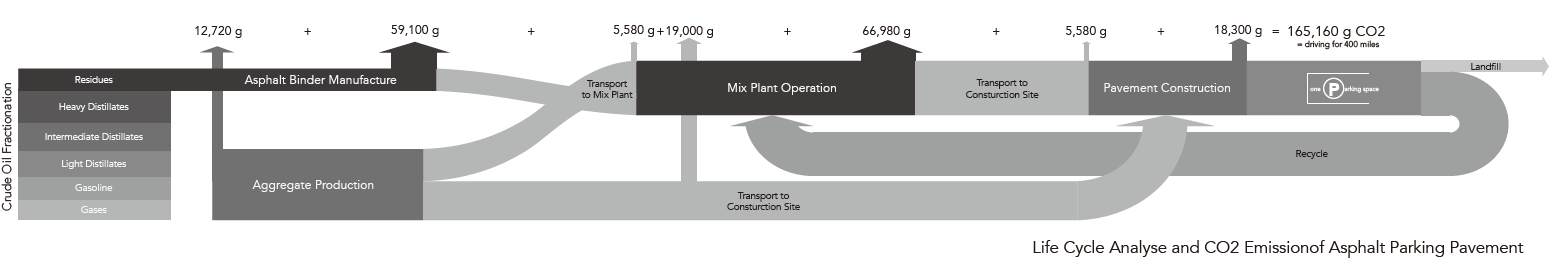

Two main material of asphalt pavement are asphalt binder (bitumen) and aggregate. Bitumen is the residue product of crude oil distillation and act as the liquid glue to bind the aggregates, which comes from mining in quarries. Part of the aggregate will be transported to asphalt mix plant to mix with bitumen, the rest to the construction site for the dense graded base layer.

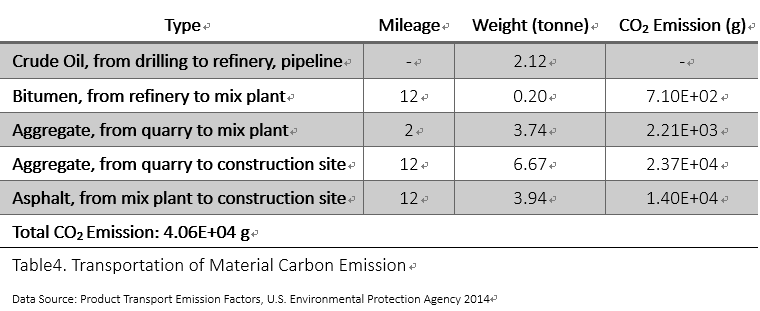

The mileage of transportation is assumed based on the condition of building surface parking in downtown Dallas, the nearest oil drilling, refinery, quarry, and asphalt mix plant were selected to calculate the mileage. The carbon emission factor is based on the Medium- and Heavy-duty Truck.

Summary

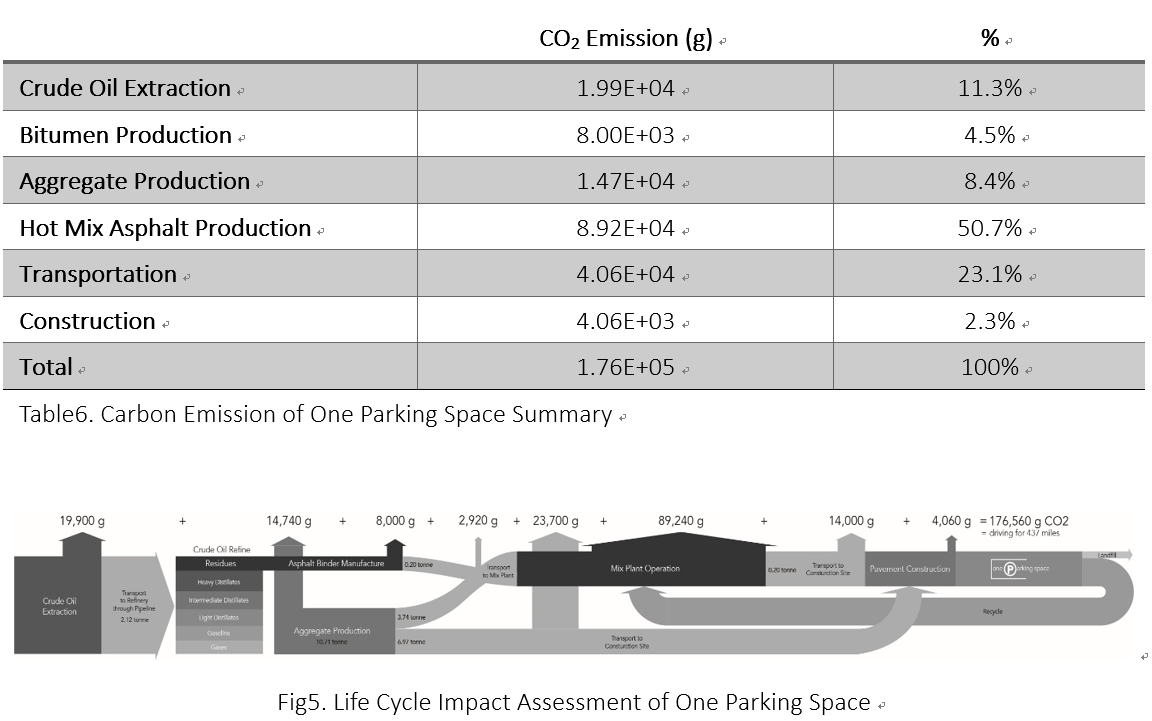

To pave asphalt for one parking space, from the extraction of raw material, production and manufacture of bitumen and aggregates, production of hot mix asphalt, to transportation of all materials and construction, emits 176,560 grams of Carbon dioxide. Among all the process, hot mix asphalt production accounts for the largest carbon emission, more than half of the total emission. However, there are researches suggest that using warm mix asphalt can reduce up to 30% of the carbon emission compared to hot mix (Hassan 2009). The second largest emission comes from the transportation.

Beside the parking space, the circulation occupies about half of the parking lot. Hence if we add the circulation, which will be the actual carbon emission of building parking lots, the number of carbon emission doubled to 353,120 grams.

Design Inspiration

Dallas is located in the blackland prairie ecoregion, named after its rich dark soil, which runs roughly 300 miles from the Red River in North Texas to San Antonio in the south. Most of the Blackland Prairie ecosystem being converted to crop production, leaving less than one percent remaining and making the tallgrass the most-endangered large ecosystem in North America.

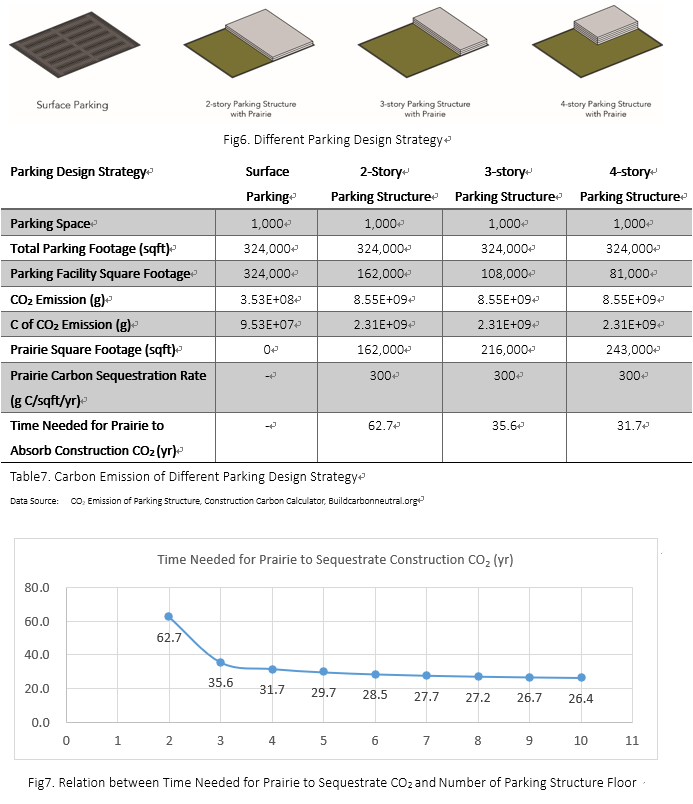

Because there is a large amount of surface parking in Dallas, they become potential invention site that can contribute to the environment. What if we stack the surface parking, turn them into parking structures, and then reclaim the rest of the land into tallgrass prairie? On one hand, the native plants are adapted to the local climate and they require less maintenance, which reduces the CO2 emission. On the other hand, it sequestrates carbon from the atmosphere and deduct the carbon emission from the construction. According to some researches of grassland prairie(Conant 2010; Haake and West 2014), one square meter of grassland prairie can sequestrate up to 4,000 grams of Carbon, among which annual and biennial sequestrate more carbon than perennial. To achieve a high sequestrate rate and to meet low maintenance requirement as well as, this research set the targeted sequestrate rate as 300 grams/square feet yr. Base on this sequestration rate, three parking alternatives were proposed, and compare to the surface parking.

Base on the assumption, if we chose a 3-story parking structure with prairie, it can significantly reduce the carbon emission compare to surface parking, while remain a reasonable height and construction cost.

Reference

Ben-Joseph, Eran. 2015. ReThinking a Lot: The Design and Culture of Parking. Cambridge, Mass.; London: MIT Press.

Buildcarbonneutral.org. “Construction Carbon Calculator.” Accessed May 9, 2018. http://buildcarbonneutral.org/.

City of Dallas GIS Services. 2015. “Impervious Area.”

Conant, Richard Theodore. 2010. Challenges and Opportunities for Carbon Sequestration in Grassland Systems: A Technical Report on Grassland Management and Climate Change Mitigation. Rome: Food and Agricultural Organization of the United Nations.

Di Mascio, Paola. 2013. “Environmental Impact Assessment of Road Asphalt Pavements” 7 (November): 1.

European Commission, and Joint Research Centre. 2010. ILCD Handbook: General Guide for Life Cycle Assessment : Detailed Guidance. Luxembourg: Publications Office of the European Union. http://lct.jrc.ec.europa.eu/pdf-directory/ILCD-Handbook-General-guide-for-LCA-DETAIL-online-12March2010.pdf.

Haake, Danelle, and B. Jason West. 2014. “Estimation of Carbon Sequestration in a Restored Tallgrass Prairie Ecosystem in Eastern Missouri.” Litzsinger Road Ecology Center, a division of the Missouri Botanical Garden.

Hassan, Marwa. 2009. “Life-Cycle Assessment of Warm-Mix Asphalt: An Environmental and Economic Perspective.” Louisiana University, Civil Engineering Class.

“PAIKY.” PAIKY. Accessed May 9, 2018. http://www.paiky.org/technical-resources/interactive-pavement-design-guide/.

Stripple, Hakan. 2001. “Life Cycle Assessment of Road: A Pilot Study for Inventory Analysis.” Gothenburg, Sweden: IVL Swedish Environmental Research Institute.

U.S. Energy Information Administration. “Refining Crude Oil - Energy Explained, Your Guide to Understanding Energy - Energy Information Administration.” Accessed May 9, 2018.

https://www.eia.gov/energyexplained/index.php?page=oil_refining.

U.S. Environmental Protection Agency. 2014. “Emission Factors for Greenhouse Gas Inventories.”